Expert Well Abandonment Engineering For James Fisher Decommissioning

They’ve [Enginuity] got a case history behind them. That product [SEALift], we thought, we could convert it, and with their support, work it into our tool. It was a good, dynamic group.

Richard Henderson, P. Eng.

James Fisher Decommissioning

About the Client

James Fisher Decommissioning

James Fisher Decommissioning (JF Decom), a subsidiary of James Fisher and Sons plc, specializes in offshore decommissioning engineering projects. Serving clients in the offshore oil and gas sector around the globe. The company offers comprehensive support for removing subsea infrastructure, structures, and jackets, as well as severance and abandonment.

They are industry leaders, having streamlined what was traditionally dangerous and expensive work into a safer and more cost-effective operation for all their clients.

Understanding the Problem

The Challenge

SEABASS is JF Decom’s innovative well abandonment tool. It is a single-trip, mechanical locking system designed for Class II wells, offering a cost-effective and quicker alternative to rig-based solutions. SEABASS improves upon current market tools, reducing operational risk and project downtime while meeting global market criteria.

The SEABASS tool, developed by Richard Henderson, Director of Engineering at JF Decom, required a sure-fire, quick release method of disengaging should things go awry mid-mission.

In-house options were explored. However, it was determined that developing and producing a decoupling tool “in-house” would be time-consuming and expensive.

Enginuity was brought in to provide offshore decommission engineering solutions to meet these challenges. Adding to the challenge, this project took place during the COVID-19 pandemic, when travel restrictions and isolation mandates were in place.

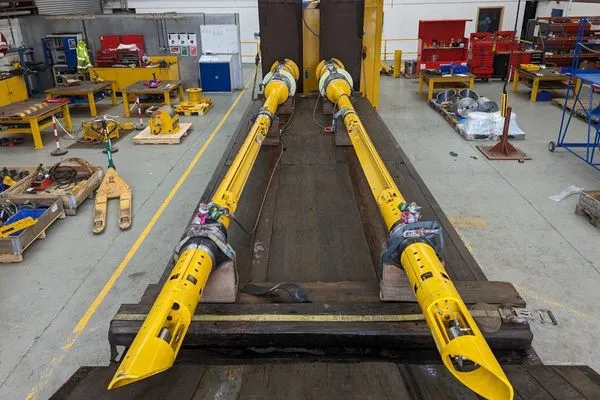

Twin SEABASS

Photo: James Fisher Decommissioning

Installation of SEABASS

photo : James Fisher Decommissioning

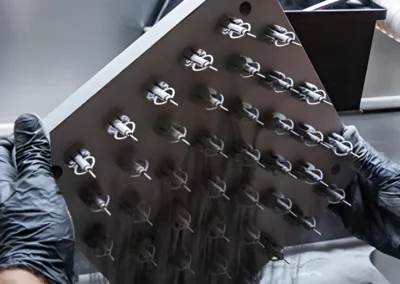

Hydraulic SEA-Lift

Enginuity's custom hydraulic SEA-Lift shown installed in JFD's valve block disconnect module.

SEA-Lift Prototype

Left: Dylan MacDonald P.ENg SEA-Lift Product Support Engineer

Right: Latest SEABASS iteration in action

Solving the Challenge

The Solution

JF DECOM engineer Richard Henderson (already familiar with Enginuity’s signature, harsh environment launch and retrieval device SEA-Lift™), sought to add an effective and completely integrated component that would help mitigate danger on a procedure of this nature.

The SEA-Lift is an ingenious device that allows the operator to connect and disconnect from subsea assets during subsea decommissioning.

A high-level viability assessment was initiated to accurately identify the specifics of the project. Identified were the following mandatory requirements:

1. The SEA-Lift decoupler would have to fit inside SEABASS tool without additional modifications.

2. The system could only be powered by the existing hydraulic system.

3. It had to work. Every. Single. Time.

The Enginuity mechanical and industrial marine teams immediately answered the call and encircled the challenge, demonstrating their proficiency in decommission engineering solutions.

Throughout the Design, Fabrication, Building, and Testing stages of the product, Enginuity and Henderson’s team moved together as one unit, despite geography and a global pandemic.

The Enginuity team had the ability to develop a highly specific component from a distance, even with the challenges that supply chain shortages and other associated issues that COVID brought with it.

Summarizing the Outcome

The Conclusion

Read the Impact

Deep. Well. Connected. The Importance of Trust and B2B Alignment

Key Takeaways

Engineering Innovation

Collaborative Efficiency

Risk Mitigation

Incorporated proven technology to reduce operational risk, ensuring safe decoupling of the SEABASS tool in emergencies.

Read Other Success Stories

See How We Are Shaping The World

Product Development

Everything you need to get your product development done quickly, creatively, and on budget.

Industry 4.0 & Robotics

Integrating traditional manufacturing and industrial platforms and practices with the latest smart technology.

Aerospace & Defence

Providing safe, controlled and reliable engineering for Aerospace and Defence projects.

Industrial & Marine

Helping you develop reliable engineering solutions for harsh environment offshore operations.