Barely three weeks before Christmas, Mike Rizkalla looks out of a window on American Airlines flight 134 and reflects upon the beauty of the Jundu mountains below. The electrical engineer and serial entrepreneur is heading back to his family in New Jersey after finalizing a deal with a factory in China. Previously involved in making the Roomba, they would now be producing his customisable smart companion for kids, Snorble®.

It has been a long, strange trip for the former guitarist of power rock outfit Bucket Truck. Since leaving Newfoundland in the late nineties to tour North America, (the band was a favourite in hard rock circles and on MuchMusic), Mike has rarely looked back. The word “interactive” has been a ubiquitous, catch-all term applied to many products from fridges to boardgames, but Mike has been a maverick in interactivity for 20 years. His Brave New World Studios is a flagship in East Coast innovation, testing the limits of Virtual, Mixed, and Augmented Reality, and now his latest invention is redefining the children’s education space.

The initial idea for Snorble was born from a moment that every parent understands, the ever-tempestuous bedtime. Mike and his wife found, like all parents, that bedtime was tough. “Sometimes even brutal,” admits Mike. The young couple was convinced that there had to be a better way to help get kids to bed. But upon googling and receiving 180 million results, there was nothing suitable to help a child sleep in Mike’s mind. Mike believed that the only way to get a child to enjoy the process of bedtime and sleeping was to make it fun, and nothing out there was doing that.

Snorble, a contraction of the words “snoring” and “adorable”, is a culmination of Mike’s diverse skill set. They are a voice-activated learning playmate that supports preschoolers and beyond in learning healthy habits, including bedtime, and preparing them for their school years. Filled with a huge catalogue of content with educational games, fun activities, catchy songs, and a whole lot of love, Snorble is encouraging and supportive day and night.

Rizkalla incorporated his extensive knowledge of computer and electrical engineering into Snorble, but was acutely aware of his limitations in product design. He realized that to be both equally safe and profitable, a product like this would have to be tested well before tooling for manufacturing was even considered. It was for this reason that he partnered with the creative engineers at Enginuity with whom he had worked before on another mixed reality product.

FEA Modelling and Enginuity

The team at Enginuity boasts an arsenal of professional capabilities and Rizkalla was keen on utilizing their expertise in mechanical simulation and, more importantly, Finite Element Analysis (FEA).

Mike and his team were aware that kids could be incredibly hard on toys, and that Snorble would have to go through rigorous testing before approval and, from there, to market.

FEA would be the only viable solution. The computer-assisted modelling and simulation analysis would allow a detailed demonstration of exactly where the weaknesses in the product appear. When subjected to this virtual testing, this method would save hundreds of thousands of prototyping and testing dollars, allowing design changes without committing to tools, molding and manufacturing.

Snorble’s team could also try different iterations of the design, reinforcing and ensuring no weak points in the casing. The FEA could simulate falls from varying heights and various angles, and the product’s detailed behaviour could be studied and adjusted.

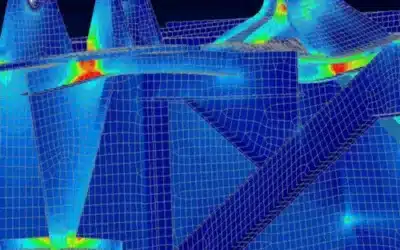

Finite Element Analysis (FEA) Example 1 – Drop Test Material & Structural Analysis Visualization of the Silicone outer shell.

Finite Element Analysis (FEA) Example 2 – Drop Test Material & Structural Analysis Visualization of the outer shell to predict how internal components respond.

This capability proved invaluable to Snorble and its stakeholders. The FEA was led by Enginuity Mechanical Engineering Lead, Louis Manuge, who embraced the challenge.

“A product like Snorble has the added complexity of a silicon outer housing that responds quite uniquely to the stress and impacts,” explains Manuge. This would prove to make the complexity of the FEA even more challenging to navigate.

It is challenges like these that both Rizkalla and the Enginuity team relish. The outcomes of thorough FEA are tangible and quantifiable. The data derived from the analysis saved an exorbitant amount of time and money while delivering Rizkalla and Snorble safely to large scale manufacturing. Additionally, this advanced engineering has resulted in a product design that surpasses product safety compliance, which is paramount in the development of children’s products.

Returning from the 20-hour voyage, Mike enters his home and sneaks into bed. He soon falls into a peaceful slumber knowing that, for now, the hard work is done. Snorble will soon be in the arms of kids everywhere.