Deep. Well. Connected.

The Importance of Trust and B2B Alignment

James Fisher Decommissioning & Enginuity Inc.

Picture this – you’re on a rolling deck of a ship in the North Sea, dawn is breaking, dark, foreboding clouds hang low in the air, there is a salty tinge on your lips, and you and your team have but one chance to decommission an abandoned well hundreds of feet below the sea.

The Objective: The safe and effective removal of contaminated fluids, placement of environmental cement plugs and removal of the wellhead to return the seabed to its natural state.

But the wells are deep, and the stakes are high.

As global energy markets swiftly transition towards diversified sustainable resources and the earliest offshore oil and gas installations reach the end of their productive life, inspired engineers to answer the call – the safe and effective decommissioning of these retired wells. This is the stated mission of James Fisher Decommissioning (JFDecom).

These offshore, sub-sea wells must be permanently plugged, and all assets safely removed while restoring the seabed, with minimal additional environmental impact.

Physically decommissioning and removing these installations in some of the most challenging conditions on earth presents tough economic, operational, environmental and technological challenges.

This is not a solitary endeavour. It involves many moving parts.

It involves a team, individuals you can trust, partners who have got your back, and partners like Enginuity Inc. and James Fisher Decommissioning.

In late 2022, James Fisher Decommissioning was preparing to decommission wells in the North Sea for a major operator and needed to be certain that everything would go to plan. Their new and innovative SEABASS™ tool had been developed by Richard Henderson and his team a couple of years prior.

Again, Dear Reader, you have one chance. You have the right tool but you also need the right partner who would have your back and join you on this journey – enter Enginuity.

Projects like this are not for the faint of heart and risk mitigation is key.

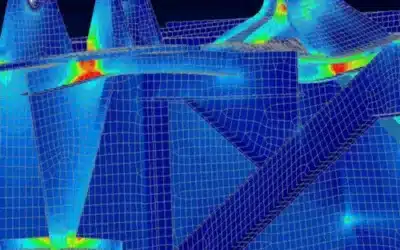

THE SEABASS tool is a well abandonment tool that performs a variety of tasks in one single trip. This deliberately designed efficiency allows for the complete removal of the decommissioned well and all associated potential contaminants with a minimum of boat time and personnel risk. But the seas are rough. And things don’t always go to plan. In the event of an emergency or breach, the SEABASS tool must be decoupled from the wellhead without any risk to the environment, the work vessel or its crew. There needs to be a way to pause the mission safely and cleanly, should something go awry.

James Fisher Decommissioning’s aim was to utilize existing technology where possible to de-risk the implementation of a new system. SEA-Lift had a track record. JFDecom could have designed something new but incorporating Enginuity’s SEA-Lift system was a much more risk-averse approach.

They needed a small, like-minded and agile firm to get the job done. So JFDecom looked across the Atlantic towards Nova Scotia to another maritime team who had the experience and know-how to develop such a product that would help mitigate the danger of a procedure of this nature.

The immensely successful SEA-Lift™, the hallmark of Enginuity’s presence in the industrial marine sector, had caught the eye of Henderson and his team at JFDecom. The remarkable simplicity, durability and effectiveness of the tool made it an obvious candidate for the needs of the project.

Furthermore, the Enginuity team was immediately responsive and understood the assignment. From the Discovery process, (a needs and viability assessment that Enginuity performs with all partnerships) throughout the Design, Fabrication, Building and Testing stages of the product, Enginuity and Henderson’s team moved together as one unit, despite geography and a global pandemic. The Enginuity team had the ability to develop a highly specific component from a distance, even with the challenges that supply chain shortages and other associated issues that Covid brought with it.

The ability to land on a Teams meeting and discuss the project and design particulars without notice is a testament of what happens when a small group of individuals like Henderson’s team embark on a project with a small, boutique firm like Enginuity – the turnaround can be astonishingly quick and agile. Initial conversations were had in September 2021 and within 12 months the product was delivered.

Both Henderson and the Enginuity team tend to see opportunity in the unlikeliest of places.

Both parties realized that remote design was possible, and potential for collaboration and relationship-building was identified early on in discussions. The idea was simple. Modify the existing SEA-Lift coupling and convert it to work with the JFDecom SEABASS tool.

“They’ve got a case history behind SEA-Lift. We immediately realized that we could possibly convert it and with their support, integrate it into our tool. And so, we had quite a few meetings, and I thought it was just a good dynamic group.” says Henderson.

Yet beyond the ease of communication and natural alignment of expertise between the two organizations, there was also a symbiosis in culture. Nova Scotia means “New Scotland” in Latin. These are the jurisdictions in which Enginuity and James Fisher Offshore are headquartered respectively. However, it must be noted that James Fisher’s Decommissioning is in Aberdeen which is very much in OG Scotland!

The working relationship went well beyond geographic nomenclature. Henderson’s team quickly realized that the team in Nova Scotia was similar in process and execution and that if anything needed fine-tuning, Nova Scotia was only a quick call away.

The design process was seamless. When two organizations share a common goal and vision and are closely aligned culturally, great things are bound to happen. The integration of Enginuity’s innovation into the SEABASS tool is a perfect metaphor for how two like-minded organizations, despite significant differences in geography, can come together quickly and efficiently to execute the project on time and on budget.

With the addition of the SEA-Lift system to SEABASS, James Fisher Decommissioning could now be certain that should an emergency occur, all operations could be suspended immediately, and the tool could be decoupled without risk to crew or the ocean environment. Operations could then be resumed another day.

As the North Sea decommissioning market is maturing, James Fisher Decommissioning is looking towards the Gulf of Mexico and other markets to become part of the solution in helping return the environment to its natural state. The SEABASS and its accompanying SEA-Lift component will continue to deliver decommissioning services to its’ clients delivering a time savings of up to 25% whilst reducing all projects’ carbon footprints in comparison to traditional methods.

The stakes needn’t be life or death when looking for a partner in which to access new markets or to improve capacity and safety in the industry. But the importance of embarking on a journey with a like-minded team cannot be overstated. The relationship between James Fisher Decommissioning and Enginuity Inc. is a testament to that idea. With a clear and shared mission, even potential catastrophic challenges can easily be tackled.

Learn more about Enginuity and Industrial Marine in the link below.

Or speak to one right now: +1 (902) 431-7931