Employers pay WCB Insurance for 4 main reasons. They care about their employees. It provides financial and medical benefits to workers injured on the job. They don’t want to get sued. It’s the law. And yet still many employers cringe at the amount they spend...

Innovations and Insights at Enginuity

Healthy Belly, Healthy Business

Linda Peers knew there had to be better way. For years, Linda Peers struggled with lactose intolerance, a condition which is associated with uncomfortable gut symptoms. To avoid this, she turned to making coconut milk in her home kitchen as a dairy alternative. By...

Human/Machine Management

Understanding Leadership’s Role in Industry 4.0

“If a machine, a Terminator, can learn the value of human life, maybe we can too.” - Sarah Connor, Terminator 2 : Judgement Day Let’s take a trip in time. Five hundred years before the Industrial Revolution, (aka the First Industrial Revolution) the waterborne city of...

Resourcefulness in Carbon Capture Technology: Research to Reality

In August 1987, the world was in a deeply dire state. Sixty years of chlorofluorocarbon (CFCs) filled refrigerators and aerosol spray cans had depleted a large part of the ozone layer to a perilous level. A future of blinded children, scorched earth and extreme...

Engineering the Future: Reshaping the Manufacturing Landscape with Automation and Robotics

As one of Canada's top robotics and automation companies, Enginuity transcends conventional boundaries, consistently pushing the envelope with novel solutions that redefine the industrial paradigm. Our growing expertise in Industry 4.0, robotics, conveying and...

Building the Future: How The Industrial Prototype Process Spurs Innovation

Manufacturers explore Automation and Robotics technology for a number of reasons; commercial advantage, worker demographics, competition from abroad or even FOMO. Automation and Robotics are making massive technological leaps quickly, but it’s often challenging for...

Maximizing Product Quality: Automated Testing in Printed Circuit Board Assembly

Manual testing can seem laborous, sloppy and time consuming in today's world of complex designs and cutting-edge technology. For electronics hardware and printed circuit board (PCB) assembly specialists like Enginuity, automated testing is a crucial element of...

Custom Jetson Carrier Boards: The Key to Unleashing AI and ML Potential

How Enginuity is overcoming external supply chain problem while helping companies navigate the AI and ML Landscape. We no longer tackle difficult issues and make important choices in the same ways that we did before the advent of AI and ML. AI and ML...

What is Overall Equipment Effectiveness? A Guide to OEE in Industry 4.0

Overall Equipment Effectiveness is becoming increasingly important as the world moves into Industry 4.0. We'll cover what OEE is, why it's important, and how to calculate it with your own processes. Overall Equipment Effectiveness is like a report card for your...

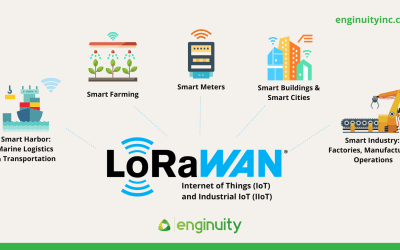

LoRaWAN: How do we enable IoT for Atlantic Industries?

LoRaWAN is the communications protocol of the future, and you could benefit greatly from it. We'll cover what it is, why we're investing in it, the different applications, and whether it could be a potential fit for your business. Enginuity is proud to announce that...

The Case for Machine Vision: What It Is, and How It Can Help You

Article Contributors: Nathan Field (Robotics and Automation Manager) | Ysa Gonzales (Marketing Coordinator)| Rhodri Armour, PhD, P.Eng (Program Manager, Industry 4.0) | Maxwell Bauer (Mechanical Engineering Co-op) | Alastair Trower (Director of Business...

When Should You Outsource Engineering Services?

Article Contributors: James Dean-Moore (Program Manager for Industrial and Marine) | Maayan Harel, P.Eng. (Program Manager for Aerospace and Defense) | Alastair "Alf" Trower (Director for Business Development) | Ysa Gonzales (Marketing Coordinator)Here's everything...

Digital Twins and Reality Capture | Integrating SDMM’s Technology in our Discovery Process

“We’re looking forward to using this technology so we can go to our customers and say, ‘here’s our strategy, and we’re going to give you an option that’s grounded in reality. Not grounded in maybe’s, nor guess-timates.”Photo courtesy of SDMM Ltd. Enginuity is proud to...

Advantages of Continuous Monitoring Systems – and Why You May Need One

It can be costly and time-consuming to deal with equipment failure when it happens. Although scheduled preventative maintenance (such as quarterly inspections) means routine checkpoints over particular periods of time, there can be a lot of unnecessary downtime...

Can Robotics and Automation Solve Atlantic Canada’s Labour Shortage?

Can Atlantic Canada's Labour Shortage be Solved by Robotics? Written by Nathan Field, Enginuity's Robotics and Automation Manager Atlantic Canada is facing a labour shortage issue that is not altogether unique in North America, but has been exacerbated due many...